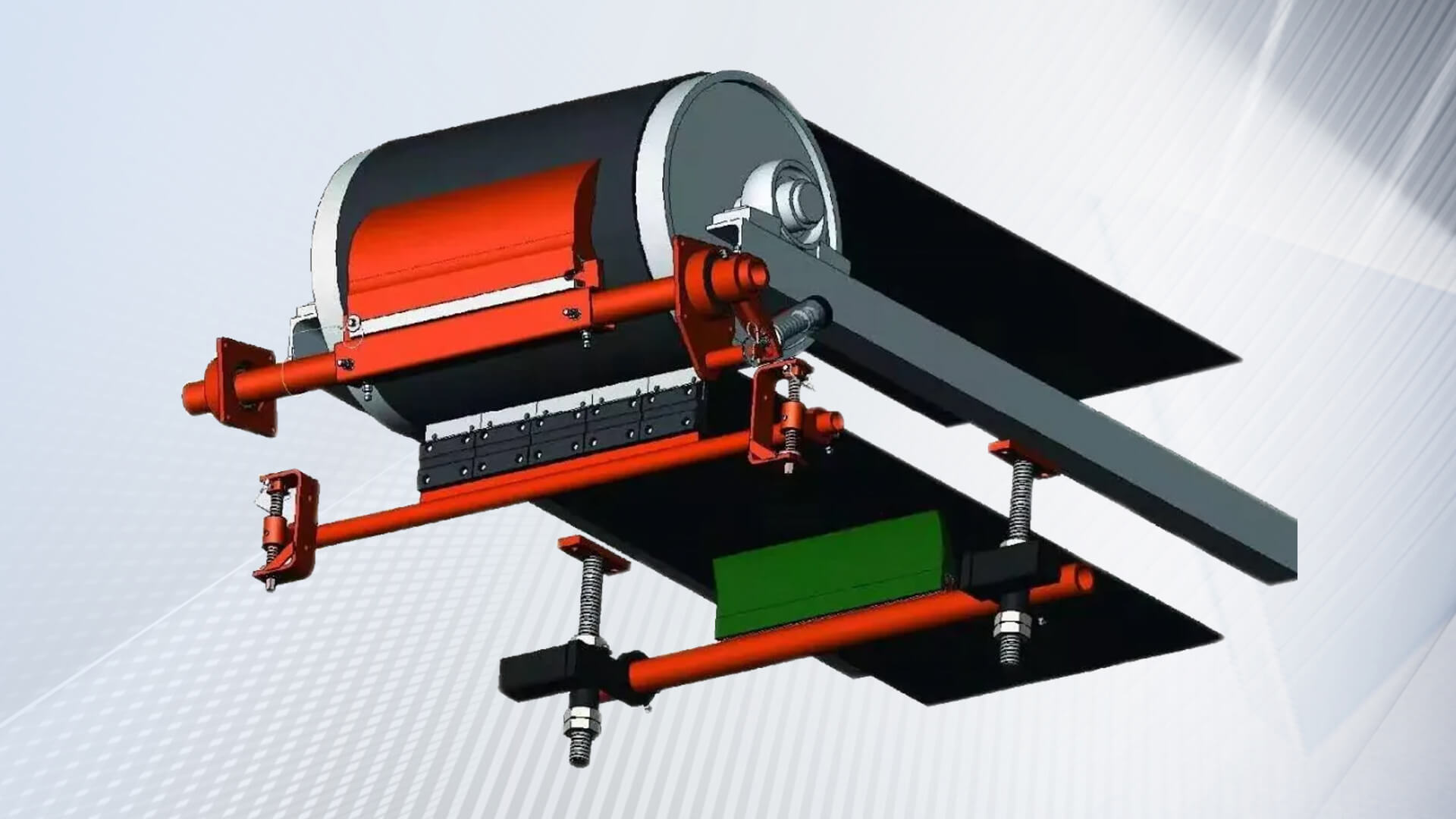

Primitive varieties of conveyor belt scraper

Primary Scrapers

Primary scrapers are often positioned near to the head pulley of the conveyor belt and are basically designed to eradicate big size residual material merely from the belt.They can help avoid material from falling on the return side of the conveyor thus curtailing pollution and belt misalignment.These are typically manufactured by materials that exhibit high resistance to wear as in the case of polyurethane or rubber and they are expected to be used in scraping large particles.Since they are easy to construct and display efficient functionality,belt conveyors are the preferred option for several conveyer systems.Secondary Scrapers

These are the final scrappers fixed after the first ones,which effectively scrapes off finer formation as well as dust likely to remain on the conveyor belt.These scrapers are mostly more easily defined and typically fabricated from a sturdier material such as ceramic or metal to enhance their efficiency in cleaning.Compared to primary scrapers,the secondary scrapers are more ideal to be used in areas that need hygiene,for instance,the food processing sector or the production of drugs.Cleaning Scrapers

Tertiary or cleaning scrapers are mainly positioned after the secondary scrapers in the tail portion of the conveyor.Their primary tasks include the last cleaning to ensure that even the minutest types of material are not carried back into the system.Cleaning scraper has wide application in industries that organize rigorous cleaning solutions such as Electronics manufacturing and Precision Processing industries.

How to Choose the Right Conveyor Belt Scraper

Belt Type

Depending on the type of material which is conveyed through the conveyor belts,different kinds of scraper will be needed.One must ensure that the scraper used is compatible with the belt and can improve performance tremendously if chosen correctly.For instance,steel cord conveyor belts are considered to be relatively more rigid than other types and as such,they demand scrapers that are of higher wear resistance and levels of hardness such as polyurethane or ceramics.Fabric conveyor belts are softer than puckered ones and therefore require scrapers with more resilience and with a harder surface such as rubber scrapers.Finally,the type of belt should first be recognized and then appropriate scraper material and structure should be chosen.Material Type

According to the conveyed material bulk characteristics,the material and design of the scraper should be chosen.Scrapers for sticky materials and the dry materials are different in their design.For instance,in conveying sticky articles,polyurethane scrapers are suitable because the material does not stick to the scraper since it is stretchy and has a high wear resistance.For dry materials,one has to use hard scrapers such as the ceramic or metal which could effectively remove the fine particles without accumulation.Working Environment

Other parameters like temperature,humidity,and corrosiveness of the working environment also affect the choice of scraper.Another issue with high-temperature environments is that standard rubber scrapers can wear down rather fast while more heat-resistant silicone or special polymers can be more durable.In wet or corrosive conditions,one should use stainless steel or scrape materials which have been coated with special materials.Installation and Maintenance Tips

1.Proper Installation of Conveyor Scrapers:Please ensure that the scraper applies approximate pressure on the belt and should not come in contact with the belt surface in a harsh/protruding manner to avoid damaging the belt of the conveyor.The proper angles and pressure on installation will facilitate the performance of cleaning tasks and lengthen the service of the scraper and the conveyor belt.2.Maintenance Tips:Inspect the scraper frequently and replace scraper blades that are worn out at the earliest.Maintain the scraper clean and in a good state.Some of the ways that can be used to improve on the cleaning capacity and the durability of the scraper include;adequate greasing and proper positioning of the scraper.

When buying a conveyor belt scraper,one should not fail to take his or her time and visually oversee the functioning of the equipment.Buying proven brands and suppliers is quality adherence and after-sales service gurantee.For instance,Zoomry with more than 20 years experience in bulk material handling targets to become a world’s leading in this sector.Their pre-sales and after-sales service professional teams,the products reach more than 50 countries,customers placed their trust in.If you are still in doubt about making the right decision,then you can talk to us for more clarification on the services we offer.

ZOOMRY

ZOOMRY