Description

The telescopic radial stacker is one of the most cost effective and efficient ways to stack materials on the market. Reducing separation, degradation, contamination and compaction during storage ensures "in-spec" material for any application. telescopic radial stackers meet the needs of a wide range of applications and industries. They provide up to 30% more stacking capacity in the same footprint when stacked in a trapezoidal configuration than with a standard conveyor.

Features and Benefits

- Industry recognized as the best inventory method for maintaining material quality.

- Up to 30% more capacity in the same footprint than conventional stackers.

- Significantly reduces separation, degradation, compaction and contamination during stacking.

- Delivers higher quality products at a lower cost per ton of inventory

- Eliminates the need for wheel loaders to building inventory - reducing labor and maintenance costs.

- Load rates up to 3,000 TPH.

- Full extension lengths up to 20 meters

- Eliminates double handling of material

Series model:

Model

Width/mm

Maximum

Capacity m3/h

Speed

m/s

Standard

length/m

Maximum

angle

Telescopic

length/m

ZR80SF

800

500

2.5

30/40/50

20°

10-20

ZR100SF

1000

850

2.5

30/40/50

20°

10-20

ZR120SF

1200

1500

3.15

30/40/50

20°

10-20

ZR140SF

1400

2100

3.15

30/40/50

20°

10-20

ZR160SF

1600

3500

4

30/40/50

20°

10-20

The above are our standard models, we can customize production according to customer needs.

We have a long and solid cooperation with SEW and Flender. Look forward for your inquiry.

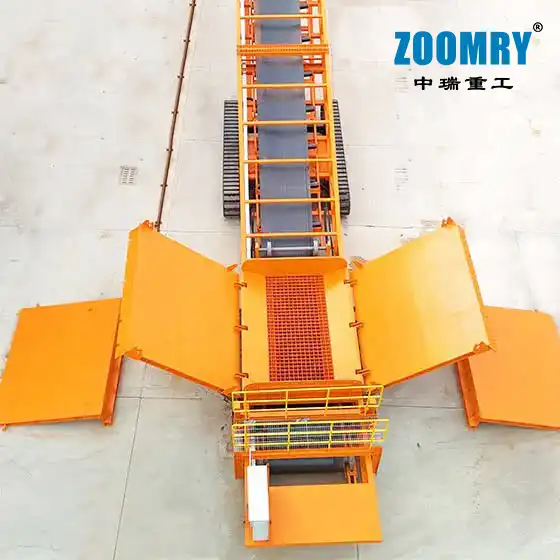

Structural composition of stacker:

1-Hydraulic lifting system 2-Front wheel walking device 3-Hydraulic outriggers 4-Hydraulic station system 5-Base 6-Electrical control box 7-Tail wheel rotation device 8-Tow bar 9-Maintenance platform 10-Hopper 11 -Main conveyor belt 12-Wire rope traction device 13-Telescopic conveyor belt

The included angle of the stacker can be controlled between 4 degrees and 20 degrees.

The front wheel traveling device is mainly composed of a traveling frame, a hydraulic motor, a traveling tire, a chain and a chain guard. The front wheel running device is connected with the base by a pin shaft. In normal use, the hydraulic outrigger will fully lift the front of the base. After the tire is off the ground, the front wheel running device will be manually rotated to expand to the working position. After reaching the working position, use the pull rods on both sides of the base to connect with the pin shaft of the front wheel running device. Then the hydraulic outriggers can be retracted and the tires are all on the ground, and then they can work normally or rotate; when the mobile stacker needs to leave the work site, the outriggers of the oil cylinder can be lifted up again, so that the tires are off the ground and then the front wheel drive device can be manually rotated At 90°, pull it away after positioning with a pin shaft. Note that the tire pressure of the walking tire is 11-12Mpa, and the maximum cannot exceed 12Mpa.

The electric control box is bolted and installed on the base. The electric control box is the operation center of the entire stocker, and all operations of the stocker are completed on the electric control box.

The tail wheel rotating device is mainly composed of a tire, a turntable, and a bracket, and the base and the fixed frame of the belt conveyor are all installed on the bracket of the tail wheel rotating device.

ZOOMRY

ZOOMRY