Product Description

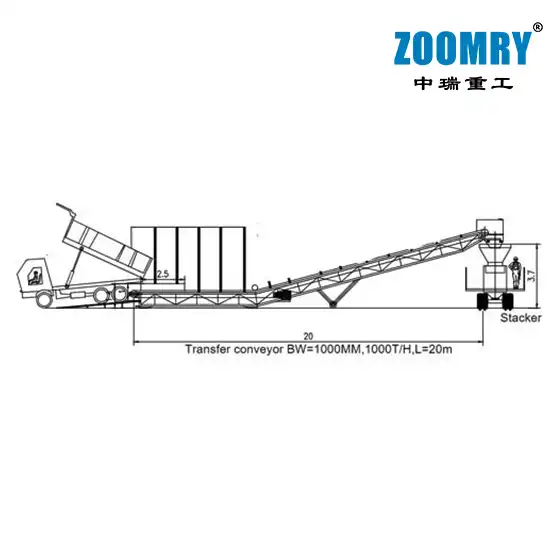

Truck unloader is an important machinery working with our ZRSF series Mobile telescopic stacker.

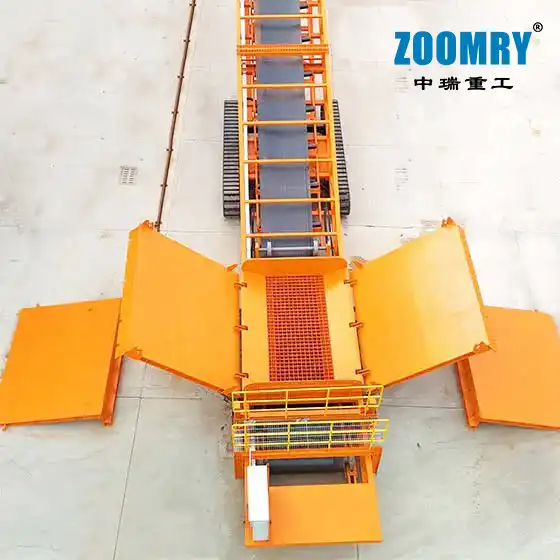

It have wheeled type and crawler type, it has a ramp for the dump truck to drive on so to dump the material into it.

There are two truck ramps or four truck ramps for choice. Transportation capacity start from 200thp- 3000tph. Belt width from 650mm- 1600mm.

Speciafications

Undercarriage

- Heavy-duty truck frame

- Maximum of the conveyor discharge height reach to 5.8m

- Super heavy duty tires optional.

- Air brakes, brake and directional lights, and mudfiaps are optional

- Hudraulic jacks to support

Low position and easy reachable receive Hopper

- Customized hopper size from 3.5m- 5.7m width to match all kinds of your wheel loaders or excavators with a widely opening

- 5.0 kw-7.5 kW electric / hydraulic power pack

- Optimized grid for kinds of aggregates or minerals

Conveyor Frame

- belt width from 800mm - 1600mm x length from 8m -20m conveyor

- Heavy-duty frame special for heavy duty dump trucks

- belt speed from 1m-4m per second

- Screw type take-up

Belt

- EP belt special for truck unloader, EP100 (5+4+2 ), EP 200(6+4+3)

- Site Vulcanized splice gives longer lifespan

- Ground accessible start / stop push button controls, radio congtrol optional

- China top brand belt which was widely used on all of our long distance belt conveyor

- LESS power cable – 380-460 volt, 3 phase, 50/60 HZ power can be designed by client's site suituation

Drive

- 300- 2200 ton per hour unloading capacity

- Dual 11 kW electric head end drive (1,800 RPM, TEFC 3/60/460)

- Gear reducers adopt international brands like FLENDER / SEW

- Backstops

- Drive pulley – 20” [508mm] diameter ceramic lagged head pulley with Haerbin® bearings

- Tail pulley – with Haerbin® bearings

Idlers

- Long life ZOOMRY idlers also for all of our long distance belt conveyor system projects

- Impact idlers in the load area

Options

- Belt cleaner

- Discharge hood

- Wireless remote control

- Hydraulic undercarriage lift cylinder

- Hydraulic landing jack

- On-board diesel GenSet – can be customized

Details

Advantage

No need for trucks to go to the stockpile area.

Simplifying the unloading process, shortening truck cycle times, speeding up material transportation and improving efficiency.

Reduced transportation and fuel costs.

Video

For belt conveyor and mobile telescopic stackers, if to make the machine running for long time, client need to do the site vulcanizing at site.

We can supply the vulcanizing machine with the telestacker or long distance belt conveyor system.

The site vulcanizing work can be done with the following steps:

How to do the site Conveyor Belt vulcanizing

ZOOMRY

ZOOMRY