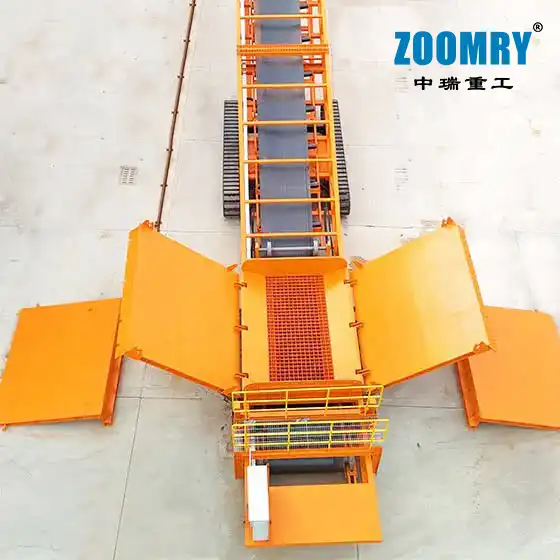

Grasshopper conveyors are designed to convey materials over long distances as conveying materials is the most cost effective and environmentally friendly method of material handling.

This jumping conveyor can be used in quarries, mining, logistics, ports and inland terminals, power stations and other industries.

Speciafication

Type

Capacitity

Length

Power of belt conveyor

Travel motor power

Max Inclination

Stack height

Belt Speed

t/h

m

kw

kw

°

m

m/s

ZR65D

200

20/25

18.5

11

18

6.5/8.0

2.0

ZR80D

300

20/25

22

11

18

6.5/8.0

2.0

ZR100D

400

20/25

30

15

18

6.5/8.0

2.5

ZR120D

550

20/25

37

15

18

6.5/8.0

2.5

The mobile transfer conveyor has the following applications:

1. mobile connection to primary/secondary processing plants in pits.2. mobile links within ports from truck unloaders/hopper feeders to ship loaders.

3. mobile links providing data for mobile ship loading systems.

4. mobile links from warehouses to ship loading/unloading in ports.

5. grasshopper conveyors for ore transportation in heap leach plants.

Advantages

1. Adjustable discharge height allows for a wide range of equipment to be discharged.

2. Eliminates/reduces loading shovel movement, thereby reducing operating costs.

3. Flexibility to move, multi-faceted stacking.

4. Saves space and allows for easy storage.

5. Can be customized to meet customer needs.

Related Mobile Conveyor Solutions

Link conveyors for transferFrom crusher to stacker

Harbor Yard Stacking

Harbor Yard Recycling

Railcar and barge loading

Recycling at the stockyard

Why you choose us?

Flexible conveyors easily shift in and out of operation depending on transfer length requirement.

Custom-engineered conveyor truss design extends conveyor life in rugged mining applications.

In-house electrical design interlocks conveyors to automatically stop production in the event of process interruptions.

Reducing operating costs and increase uptime.

More details:

Grasshopper onveyors are comprised of field bolted prefabricated truss sections. One end is elevated by struts from an axle equipped with tires.

The transfer or grasshopper conveyors are moved around the site pads by the use of a large fork truck or front-end loader.

Video

ZOOMRY

ZOOMRY