Description

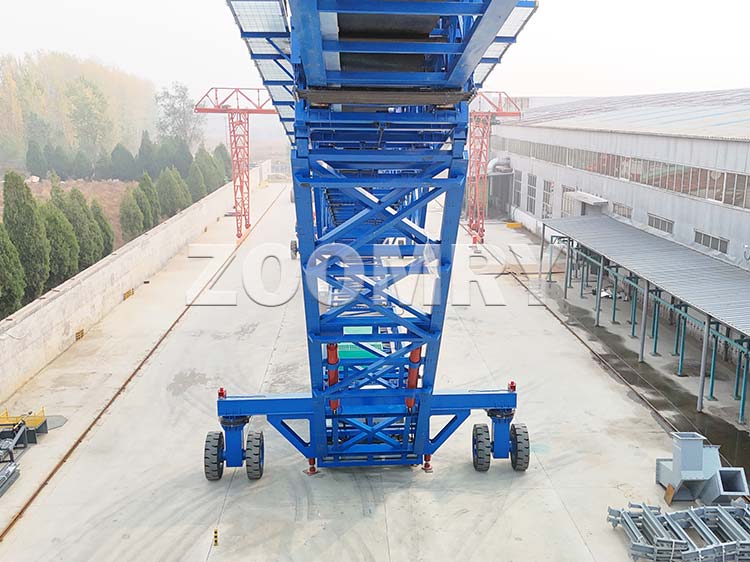

The radial telescopic ship loader is an advanced piece of equipment used in ports and terminals for efficiently loading bulk materials onto ships. The radial and telescoping features allow operators to easily trim hatches or multiple hatches from a single feed position, reducing hatch changeover time and production downtime. They can easily load vessels up to Panamax size and offer complete mobility, chute and dust suppression/vacuum options for specific applications and materials.

Why you choose mobile radial telescopic ship loader?

1. Telescoping and radial features provide unmatched trimming capabilities for the majority of vessel sizes at various port, terminal, dockside, etc. scales.

2. It has powered wheels, tracks, rails, and a combination to fit a whole range of jetty/quayside designs for its comprehensive on-site mobility.

3. Complete feed-in, transfer, and discharge ports that are completely sealed to prevent spills on the job site, as well as choices for dust extraction and suppression for handling a wide range of bulk materials

4. The loading rate of barge ships is about 3,000 TPH. With the help of our radial telescopic ship loader, you may have a very effective ship loading system.

5. Our radial telescoping barge loader can fulfill diverse requirements of loading bulk materials on different sized ships, and it has fully expanded lengths up to 58 meters.

Applications

1. The Radial Telescopic Shiploader for iron ore is designed for loading barges, Coaster, Handysize, Small Handysize and Panamax vessels.

2. Fully maneuverable for use in ports of different sizes to load a variety of vessels.

3. Capable of handling various materials such as coal, grain, fertilizer, ores (iron, copper, gold, bauxite), aggregates, wood chips, wood pellets, sulfur, cement clinker, etc.

4. Can easily feed from stationary conveyor systems, wheel loaders, trucks, overhead conveyors, trip conveyors and many more.

Features

The Radial Telescopic Shiploader for iron ore can Easy trimming of 3 hatches from one feed positionParallel drive wheels for fast "hatch" times and telescoping to "pass" through the gear boat's infrastructure

Telescopic function ensures unrivaled trimming ability

Fully sealed/dustproof/dust extraction option

Telescopic and cascade chutes available

Can be moved "off-site" when not in use

Options

Mobility - Drive wheels (inline, parallel, radial patterns), track mounted (harsh ground conditions), wheeled and rail mounted.Dust protection - galvanized/canvas dust cover, retractable dust cover, dust extraction, integrated retractable chute (free-fall - cascade design), 360-degree trimmer chute, rubber "sock" chute, water suppression and more.

Sealing of all transfer points, including side panels and bottom trays.

Electrical integration - communication interconnections, radio remote control, fully integrated generator, Ethernet connectivity and more.

Marine specification finishes.

How to load bulk materials onto ships efficiently is an unavoidable problem in terminal operation and management. Bintulu Port, a state-owned port in Malaysia, is a large deep-water port that can berth large bulk carriers of 50,000 to 120,000 tons, including Barge, Handy size, Handymax, Panamax and Capasize. The main materials handled by the Port Authority are Palm Kernal expeller, Palm Kernal shell, referred to as PKE/PKS, and fertilizer. In the future, they may also load some iron ore in to ships.

Based on the above needs, the Bintulu Port Authority began to investigate excellent mobile ship loaders factories in the market. They soon found and contacted ZOOMRY heavy industry co., ltd. located in Hebei Province, China. This is a high-tech enterprise that has been specialized in the research and development and manufacturing of bulk material conveying equipment for many years. Their main products are divided into intelligent equipment, such as: mobile shiploader, telescopic shiploader, radial shiploader, mobile stacker, truck unloader, portable grasshopper etc. Conveyor system, such as: long-distance overland belt conveyor, pipe belt conveyor, etc. ZOOMRY has many years of experience in the production and manufacturing of mobile ship loaders. They have been deeply involved in the bulk material conveying industry for many years and have their own high-quality long-life rollers and pulley. The service life of the trough-type heavy-duty rollers can reach more than 50,000 hours. They have an independent production line and has been supplying high-quality belt conveyor rollers to the market for a long time. The rollers use seamless steel pipes from steel mills as special roller tubes, which have the characteristics of low radial runout, good roundness, low noise, and good wear resistance. Since 2018, ZOOMRY, with the support of the company's strong engineering team and existing belt conveyor design and production experience, has started to provide the market with mobile shiploader, telescopic shiploader, radial shi

ZOOMRY

ZOOMRY