Description

The Mobile Ship Loader for PKE PKS has a throughput of up to 800 to 3000 tons per hour. It offers short berthing times and is a reliable bulk material loader. A ship-loading conveyor is a versatile piece of equipment used in ports and terminals to load bulk materials such as coal, ore, grains, and other commodities onto ships. It is designed to be mobile and can be easily moved along the quay or dock to reach different loading points on various vessels. Mobile ship loaders offer several advantages, including increased efficiency, flexibility, and reduced infrastructure requirements.

The operation of a Mobile Ship Loader for PKE PKS involves the following steps:

Positioning: The mobile ship loader is positioned at the appropriate location on the dock, aligning it with the cargo hold of the ship to be loaded.Conveyor Setup: The conveyor system is extended and configured to the required height and angle to reach the ship's cargo hold.

Material Loading: Bulk materials are fed onto the Conveyor Belt from the storage area, which could be a stockpile or a storage facility near the dock.

Loading Onto Ship: As the conveyor moves, the materials are transported along its length and deposited into the ship's hold. The conveyor's adjustable height ensures even distribution of the material within the hold.

Monitoring and Control: Operators oversee the loading process using various controls and monitoring systems. These systems help regulate the flow of materials, prevent overloading, and ensure safe and efficient loading.

Adjustments: If needed, adjustments are made to the conveyor's height, angle, and loading rate to accommodate the ship's changing draft (the depth of the ship in the water) as it is loaded.

Completion and Moving: Once the ship's hold is adequately loaded, the conveyor is retracted, and the mobile ship loader can be moved to another loading point on the dock or to a different vessel.

Mobile ship loaders offer advantages in terms of reducing infrastructure costs since they eliminate the need for fixed loading equipment. Additionally, they allow for quicker loading and unloading operations, which can lead to reduced turnaround times for ships at the port.

Features

1) Excellent Conveyor Parts

ZOOMRY is designing and producing kinds of CEMA standard idlers and pulley by ourselves, this guarantee ZOOMRY conveyors’ quality steady and good. And the ship loaders are adopting FLENDER/SEW motors with best quality China brand bearings. DIN standard conveyor belt to be environment friendship.

2) Galvanized Rain Cover / Sliding Canvas Cover

Rain Covers are available in galvanized steel, aluminum, stainless steel, fiberglass or painted steel. Screens are optional to shield the return belt to keep workers safe from moving components and block access for animals. Sliding canvas cover retracts and extends with the conveyor to protect material and prevent dust.

3) Telescoping Discharge chute

A telescopic conveyor allows 30% extension and retraction for fully trimmed hatches and adjustability around unique vessel infrastructure.

4) Onboard Diesel Power-Gen Group

ZOOMRY optimized diesel power-gen set allows flexibility to quickly move anywhere throughout the dock!

5) Zoomry Under Carriage

Hydraulically-powered undercarriage designed to support system move flexible and be stability. We have basic type, wheeled dolly type, tracked type and full wheel drive type to suit different working site or requirement.

6) Heavy-Duty Load Idlers

Large idlers support conveyor while center pivot design guarantee weight equally shared on all rollers. Our designed and produced ZOOMRY brand super idlers can suit belt speed up to 6.9 m/s. Roller life can last to 50,000-60,000 hours.

Specification

|

|

DWT (ton) |

Clearance Height(m) |

ZRSL -33 |

ZRSL-46 |

ZRSL-52 |

ZRSL-58 |

|

BARGE |

100-5,000 |

0-3 |

|

|

|

|

|

HANDYSIZE |

10,000-35,000 |

4-8 |

|

|

|

|

|

HANDYMAX |

35,000-50,000 |

6-10 |

|

|

|

|

|

PANAMAX |

60,000-80,000 |

10-14 |

|

|

|

|

|

CAPASIZE |

80,000-12,000 |

16 |

|

|

|

|

Detail

Product name/description:mobile shiploader, telescopic shiploader, radial shiploader,

Bulk Material can be transported:PKE/PKS, iron ore, marine sand, sulphur, fertilizer, aggregates, stone and sand

Vessels can be used on:Barge, Handy size, Handymax, Panamax, Capasize

Rated capacity of the mobile shiploader:300-8400 tons per hour

Charactors of the telescopic mobile shiploader:heavy duty, high efficiency, for bulk material, super mobility, with power Genset on board,

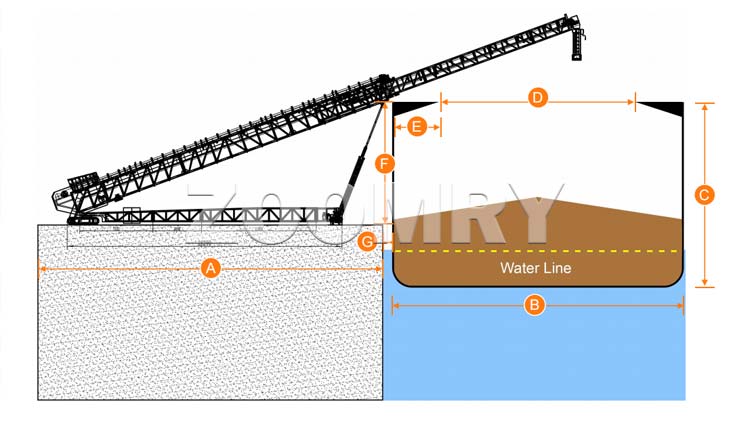

A Available Dock Width, B Beam Width, C Vessel Height

D Hatch Width, E Deck Width, F Height Above Dock

G Fender Width, Vessel type you can choose: 1. Barge 2. Handysize 3. Handymax 4. Panamax 5. Capesize 6. Others

What are the uses for mobile shiploaders?

The primary purpose of the mobile ship loaders is to load PKE/PKS (Palm Kernal expeller,Palm Kernal shell) cargo onto ships or barges. For cargo runners, it offers a highly effective loading method. Our company offers full ship loaders (also known as ship loading systems), barge loaders (also known as barge loading systems), and vessel loaders (also known as vessel loading systems). Our equipment can be used to load a ship from vehicles or stockpiles. When handling bulk materials including bulk coal, fertilizer, aggregate, sand, wood chips, wood pellets, crushed rocks, grains, iron ore, copper ore, bauxite, etc., our mobile barge loader conveyor system equipment is frequently utilized.

What kinds of conveyors are there for ship loading?

1. Rail-mounted Shiploader, 2. All Wheel Travel Shiploaders;

3. Tracked Radial Telescopic Shiploaders, 4. Direct Feed Barge Shiploaders;

5. Transshipping Barge loaders; 6. Others.

Why Would You Want to Purchase a Palm Kernal expeller,Palm Kernal shell (PKE/PKS)Ship Loading Conveyor?

1. Lower Investment: Compared to highly engineered, stationary systems, there is a significant reduction in capital investment.

2. Faster lead times in comparison to fixed systems requiring a lot of engineering.

3. Quick Installation: As opposed to taking weeks or months, installation timelines are measured in hours and days.

4. High Mobility: Shiploaders with high mobility can enter and exit your business quickly.

5. Strong Function: Stockpiling, loading, and unloading operations are all carried out by multifunctional machinery.

6. Quality Control: Our mobile ship loading equipment ensures that the quality of the bulk material is maintained throughout the conveyor handling operation.

|

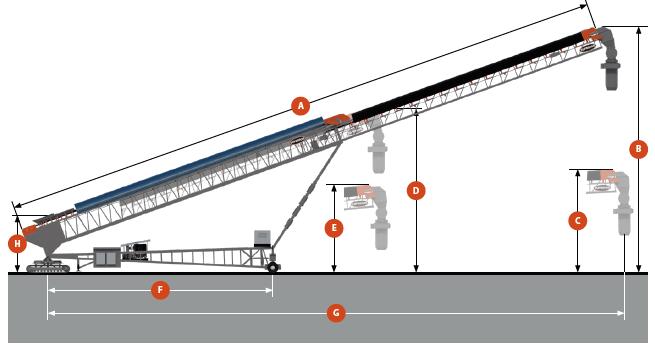

OPERATING DIMENSIONS |

|

ZRSL-45(m) |

ZRSL-52(m) |

ZRSL-60(m) |

|

Conveyor Length |

A |

45 |

52 |

60 |

|

Highest Extended Discharge Height |

B |

16.9 |

19.1 |

21.1 |

|

Lowest Extended Discharge Height |

C |

4.6 |

4.9 |

5.9 |

|

Highest Retracted Discharge Height |

D |

8.9 |

11.8 |

12.8 |

|

Lowest Retracted Discharge Height |

E |

4.0 |

4.6 |

4.7 |

|

Anchor Pivot to Center of Axle |

F |

20.2 |

23.7 |

24.9 |

|

Anchor Pivot to Discharge |

G |

42.2 |

49 |

54.6 |

|

Feed Height |

H |

3.5 |

3.6 |

3.8 |

|

Operating Width |

|

9.8 |

9.8 |

10 |

|

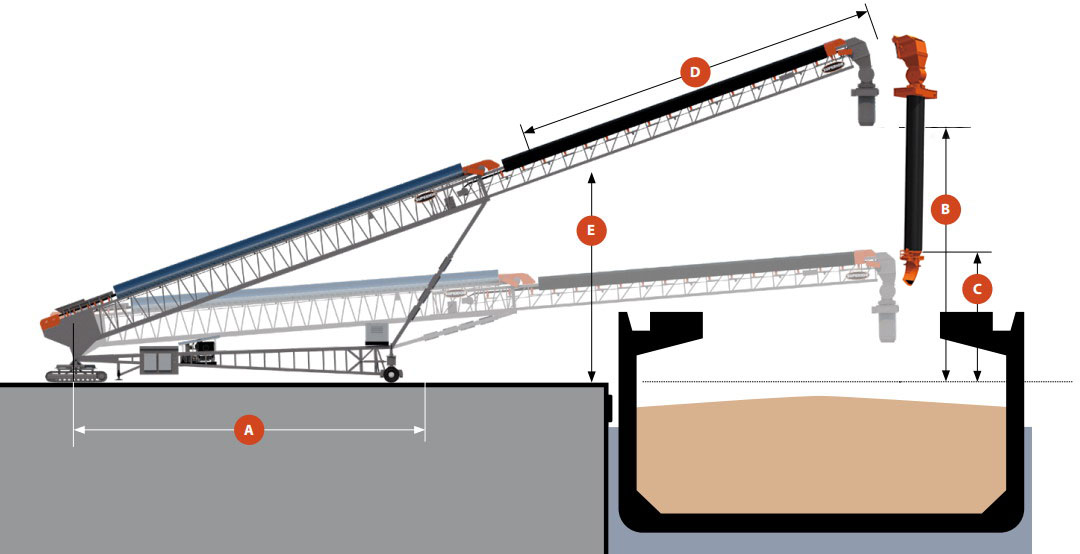

Operating Dimensions |

|

ZRSL-45(m) |

ZRSL-52(m) |

ZRSL-60(m) |

|

Undercarriage Length |

A |

21 |

24.8 |

26.1 |

|

Clearance (Raised) |

B |

14.5 |

16.7 |

18.6 |

|

Clearance (Lowered) |

C |

4.6 |

4.9 |

5.9 |

|

Stinger Conveyor Extension Distance |

D |

18 |

19 |

24 |

|

Max Height of Main Conveyor |

E |

7.5 |

9.5 |

10.1 |

|

Operating Dimensions |

|

ZRSL-45(m) |

ZRSL-52(m) |

ZRSL-60(m) |

|

Maximum radial travel distance of extended conveyor at 90°Arc |

A |

62.4 |

68.6 |

76.7 |

|

Distance from rear of conveyor to edge of jetty |

B |

29.8 |

36.6 |

39.4 |

|

Distance from rear of conveyor to discharge point |

C |

44 |

50 |

56 |

|

Minimum radial travel distance of retracted conveyor at 90°Arc |

D |

28 |

33 |

34 |

|

Stinger conveyor extension distance |

E |

18 |

19 |

24 |

|

Total radial angle |

|

90° |

90° |

90° |

How to load PKE/PKS (Palm Kernal expeller, Palm Kernal shell) onto the vessels in high efficiency?

How to load bulk materials onto ships efficiently is an unavoidable problem in terminal operation and management. Bintulu Port, a state-owned port in Malaysia, is a large deep-water port that can berth large bulk carriers of 50,000 to 120,000 tons, including Barge, Handy size, Handymax, Panamax and Capasize. The main materials handled by the Port Authority are Palm Kernal expeller, Palm Kernal shell, referred to as PKE/PKS, and fertilizer. In the future, they may also load some iron ore in to ships.

Based on the above needs, the Bintulu Port Authority began to investigate excellent mobile ship loaders factories in the market. They soon found and contacted ZOOMRY heavy industry co., ltd. located in Hebei Province, China. This is a high-tech enterprise that has been specialized in the research and development and manufacturing of bulk material conveying equipment for many years. Their main products are divided into intelligent equipment, such as: mobile shiploader, telescopic shiploader, radial shiploader, mobile stacker, truck unloader, portable grasshopper etc. Conveyor system, such as: long-distance overland belt conveyor, pipe belt conveyor, etc. ZOOMRY has many years of experience in the production and manufacturing of mobile ship loaders. They have been deeply involved in the bulk material conveying industry for many years and have their own high-quality long-life rollers and pulley. The service life of the trough-type heavy-duty rollers can reach more than 50,000 hours. They have an independent production line and has been supplying high-quality belt conveyor rollers to the market for a long time. The rollers use seamless steel pipes from steel mills as special roller tubes, which have the characteristics of low radial runout, good roundness, low noise, and good wear resistance.

Since 2018, ZOOMRY, with the support of the company's strong engineering team and existing belt conveyor design and production experience, has started to provide the market with mobile shiploader, telescopic shiploader, radial shiploader, mobile stacker, telescopic stacker, radial stacker, crawler type stacker, fully hydraulic shiploader, fully hydraulic stacker and truck unloader, grasshopper etc. Mobile shiploaders have two main functional modules, one is the conveyor part, and the other is the chassis of the construction machinery. The conveyor part is the core advantage of ZOOMRY for more than 20 years. The chassis of the construction machinery benefits from China's strong supporting capacity for construction machinery, combined with ZOOMRY's own understanding of equipment such as dock ship loaders, and has also been continuously optimized.

At present, ZOOMRY mobile shiploader series products are the fourth generation of products, and many optimizations have been made to the mobility, flexibility and durability of the ship loader on the dock. ZOOMRY shiploader has crawler type, wheel type (not self-propelled) and fully hydraulic wheel type (self-propelled). The crawler type is also called tracked type. It uses the chassis of the well-known Chinese excavator SANY, which can adapt to harsh terrain and has the flexibility to operate in narrow spaces on the dock. Tracked type shiploader can move forward/backward, inline, vertical direction movement and also can do radial movement for enhance shiploading efficiency. However, in order to better meet the requirements of more docks for mobile shiploader products, ZOOMRY also launched a fully hydraulic wheel type shiploader, which can also move forward/backward, inline, vertical direction movement and also can do radial movement.

ZOOMRY

ZOOMRY