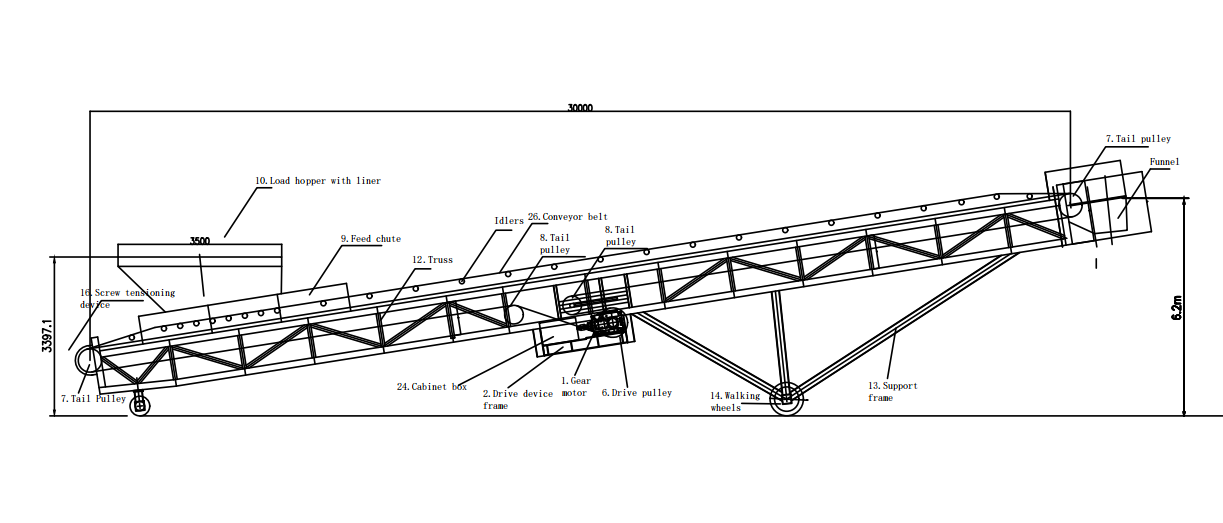

Typically,a Grasshopper Conveyor is made up of a conveyor belt,drive rollers,a support frame,and a mobile chassis.Equipped with wheeled or tracked chassis,it can move flexibly at the work site.The conveyor belt is usually made of wear-resistant rubber or synthetic materials to handle different types of materials.The support frame is designed to be lightweight for easy disassembly and assembly,suitable for temporary or short-term projects.

How a Grasshopper Conveyor Works

It comprises multiple short sections of conveyor belts connected by joints.An electric motor or hydraulic motor provides power to the conveyor belt.Materials are transported from the feed end to the discharge end,achieving horizontal or slightly inclined transport.In environments requiring high flexibility,the support frame has wheels or tracks for free movement and position adjustment.Additionally,for remote sites without engineers,it can be equipped with advanced control systems,operated via human-machine interface(HMI)or remote control,allowing real-time monitoring and adjustment.

Applications of Grasshopper Conveyor

Mining

In mining,it is used for stacking and transporting ore.Its flexibility and efficiency allow it to operate in narrow mine shafts,quickly and efficiently moving ore from the extraction point to the designated stacking area.Construction Sites

Construction sites have diverse material handling needs.Its mobility and flexibility make it an ideal choice.Whether it's sand,cement,or steel bars,they can all be efficiently transported to the required location using a Grasshopper Conveyor.Warehousing

In large warehousing centers,it can optimize space utilization,reduce stacking time,and improve work efficiency.Its precise stacking and handling capabilities make it excellent for inventory management.

Choosing a Grasshopper Conveyor:What to Consider

Material Characteristics

Select the appropriate conveyor belt material and drive device based on the material's characteristics.For high-temperature materials,choose heat-resistant conveyor belts.For corrosive materials,choose belts made of corrosion-resistant materials.Work Environment

Different work environments require different specifications.In high humidity environments,choose waterproof conveyor belts.For harsh outdoor environments,select wear-resistant and weather-resistant belts.Equipment Performance

Consider the conveyor's capacity,mobility,and control system's sophistication.Efficient drive systems and intelligent control systems significantly enhance work efficiency and operational convenience.When purchasing a Grasshopper Conveyor,choose reputable manufacturers and suppliers to ensure the quality and after-sales service of the equipment.Customization based on specific needs is also recommended to ensure the purchased equipment perfectly suits your work environment and material characteristics.If you have further questions or needs regarding Grasshopper Conveyor,you can contact Zoomry for detailed consultation.We provide professional advice and solutions to help you choose the best Grasshopper Conveyor,improve production efficiency,and reduce operating costs.

ZOOMRY

ZOOMRY