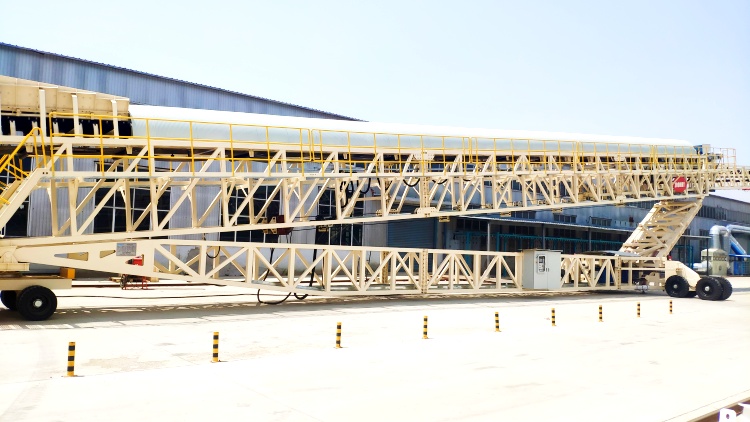

Telestack is incredibly supple in handling materials,so as to be an efficient equipment.The arm can be extended out or it can have a conveyor that is extendable.This is because of the fact that it has the ability to shrink and expand to fit various work areas.Like this,it will be able to pile materials with high precision.

How Telestack Works

The functioning of Telestack depends on hydraulics and motors.The cylinders and pumps in the hydraulic system generate power for the machine.This power makes the telescopic arm adjustable hence enabling it carry heavy loads with ease.In addition,this system provides stability and accuracy when stacking loads.There are motor drive systems for such machinery.They facilitate quick movement and adjustment of both the conveyor and telescopic arms.These enable uninterrupted action as well as guaranteed performance under heavy overload.The system may also come with a sophisticated control.It may either use human-machine interface(HMI)or remote control.The latter helps operators monitor machines in real-time.Its safety ensures a smooth stacking process.

Applications of Telestack

Mining Industry

● Ore Stacking and Handling:Telestack's can be stretched to fit in narrow mine shafts.It is quick at moving ore from the extraction point to the stacking area.

● Coal Mines:Reliable material handling systems are required for coal mines.These must be extremely strong.Telestack’s wear-proof design and large capacity make it suitable for use in high-load environments.This results in reduced downtime as well as maintenance costs.

● Metal mines:Telestack can accurately control stack heights and positioning for heavy metal ores.This ensures better storage and transportation,as well as the safety and stability of piles.

Ports

● Bulk Cargo Loading and Unloading:In ports,Telestack is very flexible.This means it can be moved around swiftly.It allows cargo loading and unloading to move faster while reducing cargo transfer losses.

● Container Stacking:Through Telestack,narrow berths have no limitations on movement.The container density of stacked containers goes up while space utilization increases during container handling.

● Ship Loading:During ship loading,Telestack supports adjustment of stacking height and position based on loading requirements of a vessel;this guarantees uniform distribution of cargo plus enhances loading efficiency.

Warehousing Centers

● Material Stacking:The big warehouses can utilize their storage spaces well through Telestack.This reduces time taken by stacks while improving work efficiency.

● Inventory Management:The accurate loading and unloading of materials by Telestack enable it to easily locate and retrieve them.This helps to increase working capital turnover as well as decrease the carrying costs of inventory.

● Automated Warehousing:Telestack is compatible with Warehouse Management Systems(WMS).It can also work in conjunction with Automated Guided Vehicles(AGVs).Consequently,this leads to a full automation of material handling.

Telestack Features

Efficiency

Telestack improves efficiency by more than 30%compared to traditional belt conveyors.It reduces transfer time linked with material handling.For companies or plants,this translates into increased production and lower costs.

Flexibility

The telescopic arm configuration permits any length change according to requirements and site conditions all over the world.Telestack can be used for different applications such as narrow warehouses or vast mines.The tracked versions,wheeled versions or hydraulic forms are some of its types.It has high mobility due to these models for quick shifting between workplaces.It is responsible for increased utilization rates.

Safety

Developed sensors and remote control systems are features of Telestack.Thus during real-time operations they track stacker’s position.This will prevent machinery damage and spillage from taking place.Telestak’s solid structure and powerful hydraulics guarantee safe operation even under high loadings.

Click the button below if you would like more information about Telestack or have any inquiries regarding it.Zoomry will respond faster providing you with the best products and services.

ZOOMRY

ZOOMRY