Product Description

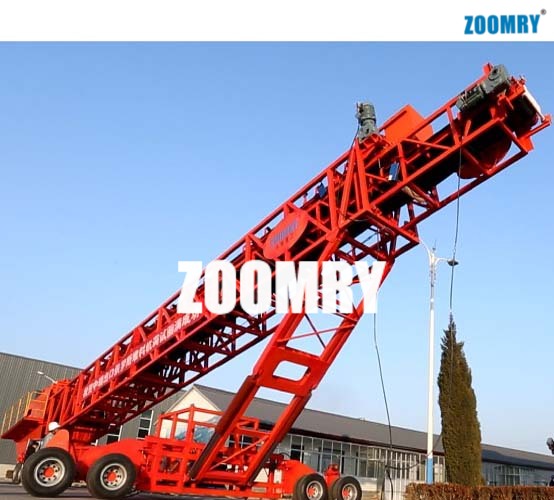

Truck unloader is an important machinery working with our ZRSF series Mobile telescopic stacker..

It have wheeled type and crawler type, it has a ramp for the dump truck to drive on so to dump the material into it.

There are two truck ramps or four truck ramps for choice.

Transportation capacity start from 200thp- 1800tph. Belt width from 1400mm- 1800mm.

Speciafications

Item

Model

Type

Belt width

Max. capacity

Optional configration

1

ZRLS-TU1400

Wheel type

1400 mm

200-1000 tons per hour

Radio control, 2/4 lines truck way,

manual/hydraulic ramp

2

ZRLS-TU1800

Wheel type

1800 mm

600-1800 tons per hour

Radio control, 2/4 lines truck way,

manual/hydraulic ramp

3

ZRLD-TU1400

Tracked

1400 mm

200-1000 tons per hour

Radio control, 2/4 lines truck way,

manual/hydraulic ramp

4

ZRLD-TU1800

Tracked

1800 mm

600-1800 tons per hour

Radio control, 2/4 lines truck way,

manual/hydraulic ramp

Undercarriage

- Heavy-duty truck frame

- Maximum of the conveyor discharge height reach to 6.3m.

- Super heavy duty tires or crawler type optional.

- Air brakes, brake and directional lights, and mudfiaps are optional.

- Hudraulic jacks to support

Low position and easy reachable receive Hopper

- Customized hopper size from 3.5m- 5.7m width to match all kinds of your heavy trucks, wheel loaders or excavators with a widely opening

- 5.0 kw-7.5 kW electric / hydraulic power pack

- Optimized grid for kinds of aggregates or minerals

Conveyor Frame

- belt width from 1400mm - 1800mm x length from 8m -20m conveyor

- Heavy-duty frame special for heavy duty dump trucks

- belt speed from 1m-4m per second

- Screw type take-up

Belt

- EP belt special for truck unloader, EP100 (5+4+2 ), EP 200(6+4+3)

- Site Vulcanized splice gives longer lifespan

- Ground accessible start / stop push button controls, radio congtrol optional

- China top brand belt which was widely used on all of our long distance belt conveyor

- LESS power cable – 380-460 volt, 3 phase, 50/60 HZ power can be designed by client's site suituation

Drive

- 200- 1800 ton per hour unloading capacity

- Dual 11 kW electric head end drive (1,800 RPM, TEFC 3/60/460)

- Gear reducers adopt international brands like FLENDER / SEW

- Backstops

- Drive pulley – 20” [508mm] diameter ceramic lagged head pulley with Haerbin® bearings

- Tail pulley – with Haerbin® bearings

Idlers

- Long life ZOOMRY idlers also for all of our long distance belt conveyor system projects

- Impact idlers in the load area

Options

- Belt cleaner

- Discharge hood

- Wireless remote control

- Hydraulic undercarriage lift cylinder

- Hydraulic landing jack

- On-board diesel GenSet – can be customized

Advantage

No need for trucks to go to the stockpile area.

Simplifying the unloading process, shortening truck cycle times, speeding up material transportation and improving efficiency.

Reduced transportation and fuel costs.

Details

Video

For belt conveyor and mobile telescopic stackers, if to make the machine running for long time, client need to do the site vulcanizing at site.

We can supply the vulcanizing machine with the telestacker or long distance belt conveyor system.

The Dawn of Bintulu Port

The salty sea breeze swirled with palm kernel fragments above the docks of Bintulu Port. General Manager Hassan's leather shoes crunched over scattered PKS debris, the sticky residue making him frown—this was the 23rd complaint about spillage caused by the old shiploader. In the distance, the 50,000-ton "Emerald Princess" sounded its horn impatiently, while the aging shiploader's arm trembled, stuck at 42 meters, falling short of the ship's cargo hold by three full container layers.

"ZOOMRY Heavy Industry's mobile telescopic shiploader can extend its boom like the ribbons of a Chinese dragon dance," Project Director Lin's voice echoed through the conference room. A holographic projection displayed a silver-gray steel beast in action: the **fully enclosed telescopic chute** extended like a serpent's tongue deep into the ship's hold, while the 1000mm-wide Conveyor Belt roared within its sealed pipeline, ensuring not a single speck of PKE dust escaped. Hassan's fingers unconsciously brushed against the sample—a million-dollar worth of raw material once lost to the sea breeze, now securely contained in ZOOMRY's leak-proof sample bottle.

The real shock came during the truck unloading simulation. When ZOOMRY's engineers activated the four crawler-type truck unloaders, the Malaysian delegation rose to their feet in unison. As the dump trucks reversed, hydraulic dust covers closed like clamshells, completely enveloping the truck tails. The 1400mm ultra-wide conveyor belts pivoted effortlessly on their crawler bases, with the intelligent control system automatically switching between two-lane and four-lane modes, leaving no tire marks on the ground. "Our power generator allows the truck unloaders to operate independently for 48 hours during a power outage," the engineer explained, patting the container-sized power unit. Outside, a sudden downpour hammered the factory roof, but the equipment's throughput remained unaffected.

Three months later, at dawn in Bintulu Port, **four mobile telescopic shiploaders** stood like a forest of steel. When the "Emerald Princess" docked again, the 52-meter boom easily reached the once-distant cargo hold, with the telescopic chute precisely discharging PKS into designated slots. The dust-covered unloading zone had become an industry marvel—twenty dump trucks shuttled between four bidirectional truck unloaders, each vehicle's dwell time reduced by 70% compared to the old wheeled equipment. The once-airborne palm dust was now entirely trapped within magnetic-sealed covers.

The headlines of <The Star> exploded at midnight: "Malaysia's First Smart Palm Port is Born!" The photo showed ZOOMRY's shiploaders tracing silver arcs under the starry sky, while the LED indicators on the truck unloaders' dust covers resembled a fallen galaxy. As Hassan answered the congratulatory call from the Prime Minister's office, he glanced at the real-time data on the monitor—the day's material loss rate was 0.03%, ten times lower than what the German supplier had promised.

As the horizon lightened with the first rays of dawn, ZOOMRY engineers were calibrating the final power generator. Lin handed Hassan a cup of coffee: "When the typhoon season arrives, you'll see the true capability of these crawler-type truck unloaders—their grip on slopes is three times stronger than wheeled equipment." The port's PA system suddenly crackled to life, announcing a new 60,000-ton vessel requesting expedited service. Hassan looked at the truck unloaders automatically switching to four-lane mode and, for the first time, smiled as he pressed the approval button.

ZOOMRY

ZOOMRY