In today’s rapidly advancing global industrialization and agricultural modernization, efficient bulk material handling and transportation have become critical demands in industries such as mining, ports, and grain processing. As a globally leading bulk material handling equipment manufacturer, ZOOMRY leverages over two decades of technological expertise to deliver comprehensive EPC solutions, including long-distance belt conveyors, truck unloaders, mobile shiploaders, and intelligent stacking systems.

Multi-Industry Applications of Mobile Shiploaders

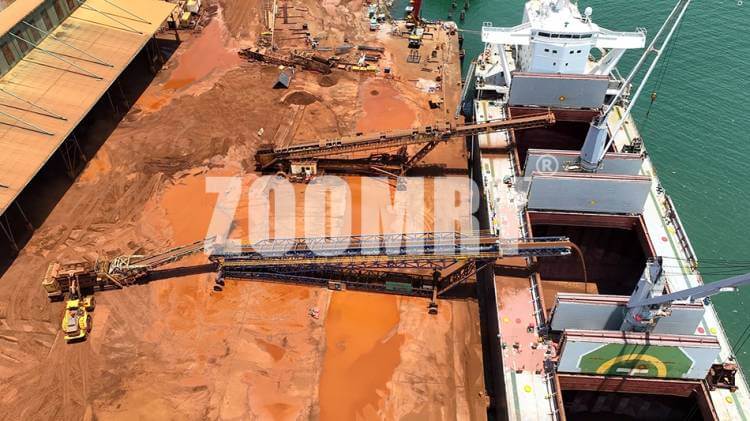

Port Bulk Material Handling

For Panamax (60,000-80,000 DWT) to Capesize (120,000 DWT) vessels, the ZRSL series mobile shiploaders from ZOOMRY, featuring fully hydraulic-driven chassis and 360° rotating telescopic booms, deliver exceptional performance in confined port spaces:

- Dynamic Operational Range Adjustment: The Mobile Shiploaders telescopic boom extends 10-22 meters with a vertical clearance of 3-16 meters, adaptable from barges to ultra-large bulk carriers. Integrated GPS positioning and draft monitoring systems ensure real-time tidal adjustments, achieving loading accuracy with ≤0.5% error.

- Precision Loading Control: Equipped with Mitsubishi PLC automatic flow regulation, the system supports preset modes for 8 materials (coal, iron ore, grain, etc.), with loading efficiency reaching 300-3,000 TPH (depending on material density) and reducing port footprint by 40% compared to fixed shiploaders.

- Environmentally sealed conveying: ZOOMRY mobile shiploaders utilize premium tubular Conveyor Belts (300-800mm diameter) combined with negative pressure dust removal systems, achieving dust emission concentrations ≤10mg/m³ and full compliance with IMO Tier III standards.

Port Scenario Equipment Comparison Table

| Parameter/Model | ZRSL-60 Mobile Shiploader | Competitive Advantages |

|---|---|---|

| Maximum Boom Length | 22m | +22% operational coverage |

| Hydraulic System Pressure | 35MPa | +25% stability in harsh conditions |

| Energy Consumption (full load) | 85kW·h | 23% lower annual operating costs |

| Corrosion Resistance Certification | ISO 12944 C5-M | 8-year extended lifespan in salt spray environments |

For further inquiries about multi-scenario solutions from a mobile shiploader manufacturer, contact us via:

- ZOOMRY Official Website

- +86 131-6401-6717

- oversea@zoomry.cn

Mining and Complex Terrain Material Handling

In projects such as Peru’s copper mines and Western Australia’s iron ore sites, the ZR-SF series telescopic stackers, ZRSL mobile shiploaders, and ZRLD-TU truck unloaders can be flexibly combined for three operational modes:

- Independent Operation: Single-unit handling of primary stockpiles post-ore crushing (15m stacking height, 28° inclination).

- Cascade Operation: Continuous material flow from unloader → stacker → shiploader, boosting system efficiency to 5,000 TPH.

- Redundant Backup: Rapid deployment of mobile equipment during mainline maintenance to ensure uninterrupted production.

Key Technologies

- 45° Gradeability: Heavy-duty crawler chassis with dual-pump hydraulic drive, delivering 280kN traction for rugged mining terrains.

- Intelligent Stockpiling Algorithm: 3D layered stacking via laser scanning, achieving <1% inventory accuracy.

- Modular Rapid Deployment: Disassembles into 8 standard container units for on-site assembly within 72 hours, reducing installation time by 60%.

Agricultural Grain Storage

For fragile grains like corn and wheat, ZOOMRY’s mobile shiploaders incorporate innovations such as:

- Low-Breakage Conveyance: Belt speed ≤2.5m/s reduces impact force by 40%.

- Food-Grade Cleaning: FDA-certified PU scrapers + pneumatic self-cleaning systems.

- Integrated Mobile Drying: Achieves seamless "unloading-drying-shipping" workflows, as demonstrated in African grain storage projects.

Technical Advantages of ZOOMRY Mobile Shiploaders

Core Parameter Comparison

| Metric | ZOOMRY ZRSL-60 | Industry Average | Advantages |

|---|---|---|---|

| Max. Capacity | 3,000 TPH | 2,500 TPH | +20% efficiency |

| Boom Response Speed | 0.5m/s | 0.3m/s | 67% faster dynamic adjustment |

| Hydraulic System Pressure | 35MPa | 28MPa | +25% stability in harsh conditions |

Patented Technologies

- Dual Redundancy Safety: Mechanical limit + hydraulic self-locking mechanisms for wire rope failure scenarios.

- Ultra-Quiet Drive Modules: Noise ≤75dB (vs. national standard ≤85dB).

- Predictive Maintenance: IoT sensors monitor bearing lifespan, reducing downtime by 90%.

Why Choose ZOOMRY as Your Mobile Shiploader Manufacturer?

-

As one of the few mobile shiploader manufacturers globally certified with CEMA (Conveyor Equipment Manufacturers Association), ISO 9001:2015, and EAC (Eurasian Conformity), ZOOMRY equipment complies with: EU Machinery Directive (2006/42/EC), Russian GOST TR CU 010/2011 safety standards, and Australian AS/NZS 4024.1 risk assessment specifications.

-

Pre-sales deployment of engineers for on-site measurement of tidal ranges, material angles of repose, and other critical parameters. 3D-based equipment layout simulation and cross-system validation of interoperability protocols (supporting Modbus TCP/Profinet) between mobile shiploaders, stackers, and unloaders.

-

Post-sales operator training programs, annual customized non-destructive testing of critical components (roller weld seams, wire rope breakage rates), and real-time IoT monitoring of 12 parameters including bearing temperature (±1°C accuracy) and vibration frequency (0-2000Hz range).

-

150,000-hour lifespan components: Idler axial displacement <0.4mm (national standard: 0.7mm), rollers manufactured with 40Cr forged steel heat treatment.

-

Mobile shiploaders support multi-scenario energy adaptability: electric drive with standard Siemens/ABB motors (explosion-proof or variable frequency options available); diesel-hydraulic systems to meet autonomous power supply needs in off-grid areas (fuel consumption ≤18L/h); hybrid power solutions integrating photovoltaic + energy storage systems, reducing carbon emissions by 30% (certified by TÜV Green Certification).

Global Project Case Studies

- Arctic Port, Russia: ZRSL mobile shiploaders operated flawlessly for 18,000 hours at -45°C.

- Southeast Asian Palm Oil Terminal: EAC-certified explosion-proof units handled materials with viscosity >5,000cp.

- South American Lithium Mine: Acid/alkali-resistant coatings + anti-static design for spodumene transport.

ZOOMRY

ZOOMRY