Correlation of the Conveyor Belt Material and the Angle

The type of material used in the belt largely determines the maximum angle through which the pipe conveyor operates.Some of the most frequently used kinds of the conveyor belt are rubber,PVC,and steel cord.Different materials have different characteristics for instance friction coefficient,wear resistance and durability determine how well it will be able to handle the different angles.The rubber conveyor belt is commonly used in applications that trains have to be at a steeper angle owing to the high friction coefficient.However for handling fine particle or powdery coal it may be more effective to use PVC belts since they offer less chance of material spillage and slippage.Steel cord belts because of their high tensile load bearing capacity and wear resistant are suitable for long-span,high-duty conveying applications.

The dependence of efficiency of mass conveyance on the angle

The turning angle of a coal conveyor is important not only in determining the stability of the material but also on the flow rates of the conveyor as well.Normally the higher inclination of the belt,the greater probability of materials slipping off the belt and hence the lower efficiency.This,therefore,poses the question of how much of the angle to increase in relation to the packing factor in order to make the best of the conveying efficiency yet not over-power the latter.For instance,when the trough angle of the rollers has been made larger,the inclination angle can be made large with no concern for material stability on the belt.Besides it is possible to improve conveyer efficiency by changing belt tension,using wider belts or convey stages.

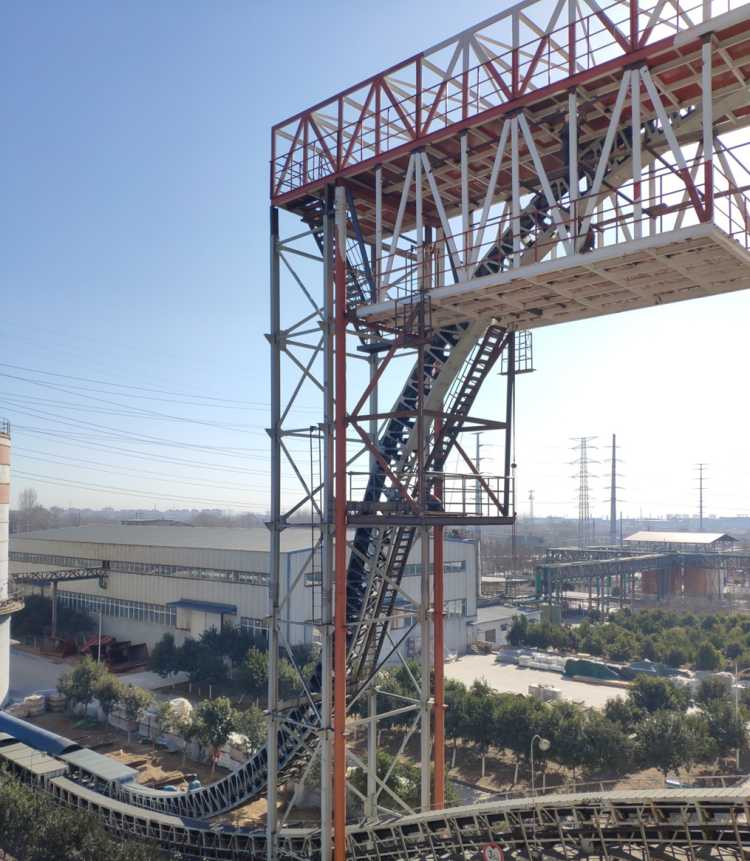

Practical Use of Coal Pipe Conveyors

In the transport of coal in mines,port and power plants,pipe conveyors have been employed in coal transport projects across the globe.For instance,in several of Zoomry’s coal pipe conveyor projects,13 out of 20 projects achieved maximum angles of 23°to 30°,the steepest of which at 30°has been successfully installed and is operating smoothly.Through reasonable design and technology optimization,pipe conveyors can take greater angles than the traditional recommendations of code as 27°.The successful application of these projects is vital importance to the pipe conveyor angle designs of future projects.

Other Methods for Increasing Conveyor Angles

To enhance the angle of pipe conveyors,Zoomry engineers have tried the following ways.For example,by raising the fill factor of the conveyor belt or,including some dividers into the belt,setors were able to raise the angle of the conveyor.Moreover,in a project of another company,a”large-angle variable-diameter pipe conveyor”realized a large-angle sealed conveyance continuously at a horizontal course of 24m and the maximum inclination of 76.5°.This not only solved the spatial cells shortcoming of but also significantly enhanced conveying efficiency.

ZOOMRY

ZOOMRY