How the Pipe Conveyor Works

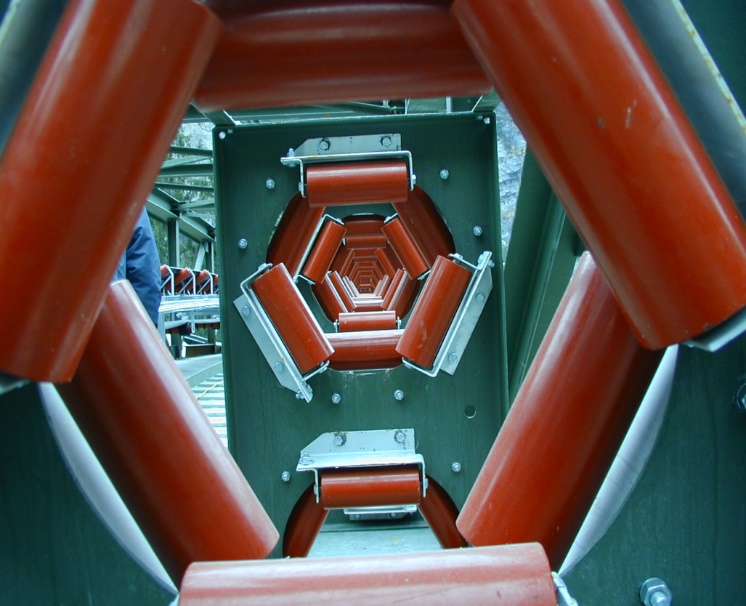

The conveyor belt serves as the medium for transmitting force and transporting materials.It is supported by flexible idler rollers,which are used to support the conveyor belt carrying materials.The driving device moves the drum by turning it.Friction makes the conveyor belt rotate around the drum.This motion moves the material.Ordinary belt conveyors do not do this.The pipe conveyor forces the belt to curl into a tube.It does this at the belt speed through a hexagonal idler roller group.This setup lets it transport materials in a sealed way.Application Scenarios of Pipe Conveyor

The pipe conveyor has an enclosed design.It also has a flexible layout.Its conveying performance is stable.It has environmental protection features.It is suitable for stable,efficient,long-distance material transport under complex terrain.It can be used in many industries:steel,mining,cement,and more.These include chemicals,ports,docks,papermaking,grain,flour,and concrete.It's also used for ore,mudstone,coal,ash,and power.

Main Components of the Pipe Conveyor

Tubular Conveyor Belt:The pipe conveyor has a tubular conveyor belt.It is the most important feature of the pipe conveyor.This conveyor belt is made of strong,wear-resistant rubber.It has steel wire ropes or canvas inside to add strength and flexibility.It can effectively prevent material leakage and environmental pollution.Driving Device:The driving device usually consists of an electric motor,reducer,and driving drum.It drives the conveyor belt to move through friction.We select the motor power based on the distance and material weight.This ensures stable conveying.

Idler Roller System:The idler roller system supports and guides the conveyor belt.It keeps the belt stable as it moves.Idlers are divided into load-bearing idlers and return idlers.Idlers that bear loads support the conveyor belt and its materials.Return idlers support the empty belt.

Tensioning Device:To ensure the normal operation of the conveyor belt,a tensioning device is required.The tensioning device can adjust the tension of the conveyor belt,preventing it from slipping or deviating from the track.

Enclosed System:The pipe conveyor has an enclosed system.It includes cover plates,side sealing plates,and other parts.They prevent materials from escaping to the outside and stop dust leaks and pollution.

Features of the Pipe Conveyor

Environmental Protection and Energy Saving:Its enclosed design can stop material leaks.It reduces dust and noise pollution.It meets environmental rules.At the same time,its high conveying efficiency and low energy consumption help to reduce operating costs.High Efficiency and Stability:It is highly efficient and stable.It uses high-strength tubular conveyor belts.It can handle large-capacity and long-distance conveying tasks.Its idler roller system and tensioning device make sure the belt stays stable and reliable.They do this during operation.

Flexible Adaptation:It can be arranged to fit the on-site environment.It adapts to complex terrain and space limits.The pipe conveyor can turn often.It performs well in such scenarios.

Low Maintenance Cost:This is due to its reasonable design,durable components,and long maintenance cycles.It also has a small daily maintenance workload.These features reduce the maintenance cost and downtime.

Considerations for Purchasing a Pipe Conveyor

Installation Services:Choose a manufacturer with fast,reliable delivery services,like Zoomry.They have very short delivery times.This ensures that the equipment arrives on time and passes tests.Certification Qualifications:The supplier must have multiple product certifications.These certifications guarantee product quality and reliability.

Product Selection:Choose the right model for your needs.This ensures the equipment meets process requirements and production capacity.

Intelligent Functions:Consider if you need smart control and monitoring.They can improve efficiency and convenience.

ZOOMRY

ZOOMRY