Telescopic Mobile stacker for sale

Specification

|

Product name |

Telescopic Stacker |

||||||

|

Material |

High Quality Carbon Steel |

||||||

|

Belt width |

800mm;914mm(36'');1000mm;1200;1400mm;1600mm; (Customer's Request) |

||||||

|

Max Capacity |

450-2400m³/h(Customer's Request) |

||||||

|

Certification |

ISO9001;CE;ISO14001;EAC |

||||||

|

Advantages |

Portable, rotatable, inclination adjustable, conveying length retractable, radial movement |

||||||

|

Application |

Mining, Port, Cement, Steel, Metallurgy, Electric Power, Coal, Machinery and Other Industries. |

||||||

|

|||||||

|

Type |

Width |

Max Capacity |

Speed |

Telescopic length |

Max inclined angle |

Telescopic length |

|

|

ZR80SF |

800 |

450 |

2.5 |

40 |

20° |

10-15 |

|

|

ZR100SF |

1000 |

700 |

2.5 |

40 |

20° |

10-15 |

|

|

ZR120SF |

1200 |

1000 |

2.5 |

50 |

20° |

15-20 |

|

|

ZR140SF |

1400 |

1500 |

2.5 |

50 |

20° |

15-20 |

|

|

ZR160SF |

1600 |

2400 |

2.5 |

55 |

20° |

15-20 |

|

The front wheel walking device mainly consists of walking frame, hydraulic motor, walking tires, chain and chain guard, which is connected with the base through the pin. Note that the tire pressure of the walking tires is 11-12Mpa, the maximum can not exceed 12Mpa.

In normal use, the hydraulic legs will lift the front part of the base completely. After the tires leave the ground, remote control the front wheel walking device to the working position, after arriving at the working position, use the tie rods on both sides of the base to connect with the pins of the front wheel walking device, then the hydraulic outriggers can be retracted, and the tires are all on the ground, so that it can work or rotate normally; when the mobile forklift truck needs to leave the work site, it can lift the cylinder outriggers again, so that the tires will leave the ground, and then it can be remotely controlled to the front wheel driving device.

The tail wheel rotating device is mainly composed of a tire, a turntable, and a bracket, and the base and the fixed frame of the belt conveyor are all installed on the bracket of the tail wheel rotating device.

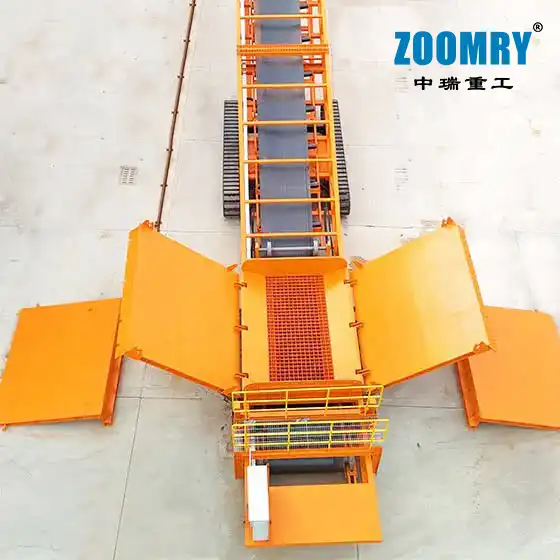

Structural composition of stacker:

1-Hydraulic lifting system 2-Front wheel walking device 3-Hydraulic outriggers 4-Hydraulic station system 5-Base 6-Electrical control box 7-Tail wheel rotation device 8-Tow bar 9-Maintenance platform 10-Hopper 11 -Main conveyor belt 12-Wire rope traction device 13-Telescopic conveyor belt

1. The telescopic length of the stacker can be adjusted, which can further increase the stacking capacity.

2. The stacker can be moved as a whole, which is convenient for users to change the location of use.

3. The stacking height can be changed by adjusting the inclination of the stacker through the hydraulic cylinder.

4. The stacker can be designed according to the user's needs.

For belt conveyor and mobile telescopic stackers, if to make the machine running for long time, client need to do the site vulcanizing at site.

We can supply the vulcanizing machine with the telestacker or long distance belt conveyor system.

The site vulcanizing work can be done with the following steps:

How to do the site Conveyor Belt vulcanizing

ZOOMRY

ZOOMRY