1. Belt Strength

The higher the strength of the mining rubber conveyor belt, the greater the weight of the material it can carry. You can find the needed belt strength from the weight of the conveyed material. Consider also the conveying distance. For long-distance and heavy-load conveying, choose a strong rubber conveyor belt. It will ensure safe and reliable operation.

2. Wear Resistance

In a mining environment, conveyor belts often face wear from materials such as ores on their surfaces. Without good damping equipment and buffer idlers, the equipment tends to become worn out quickly. The belts are made of high-quality rubber. They resist wearing well. When used with good damping and buffering equipment, they can last a long time in harsh conditions. This lowers how often they need replacing and the cost of maintenance.

3. Heat Resistance

In some mines, the materials on the belts are very hot. Ordinary rubber belts can easily melt or bend. So, when selecting, you must choose products with strong heat resistance. They can keep transmission stable in high heat.

4. Oil Resistance

In mining operations, some materials are special and contain oily components. Considering other factors is important. So, choose an oil-resistant rubber conveyor belt. It can resist grease corrosion on the conveyor belt. This extends the belt's life and avoids extra costs.

5. Tear Resistance

During the transportation of mining materials, contact with sharp objects is inevitable. The belt isn't tough enough. So, it will likely tear or be damaged during transport. Therefore, tear resistance is also a key factor to consider when choosing a mining rubber conveyor belt. A rubber conveyor belt is tear-resistant. It can reduce the risk of tearing when it encounters sharp objects. This ensures the safe operation of the conveying system.

6. Joint Method

Common conveyor belt joint methods include mechanical joints. They also include cold adhesive and hot vulcanized joints. Mechanical joints are handy and fast but weak. Cold adhesive joints are stronger. They work for small and medium-sized conveyor systems. Hot vulcanized joints are the strongest. But, pros and special gear are needed to use them. They work for large conveyor systems. Reasonable selection according to actual conditions can reduce unnecessary trouble.

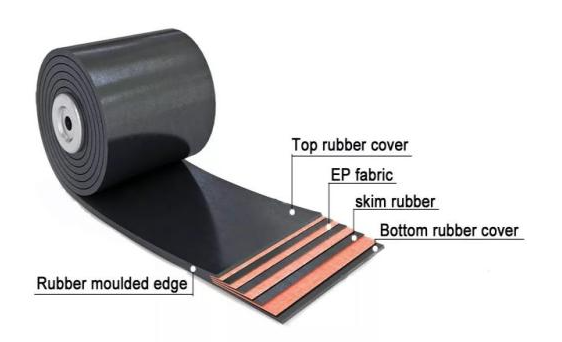

7. Conveyor Belt Width and Thickness

The design of the conveying equipment and the size of the conveyed material determine the needed belt width and thickness. This choice is crucial. A rubber conveyor belt needs to be wide and thick. This keeps materials stable. It prevents spills and belt overloads.

8. Equipment Type

According to specific needs, choose the appropriate type of belt conveyor, such as fixed, telescopic, or large-angle, etc.

Zoomry, as a professional manufacturer of rubber conveyor belts for mining, possesses extensive industry experience and a wide range of conveying equipment. Our mining projects span over 50 countries worldwide, covering more than 1,000 regions. For further assistance, please click [Contact Us] to get the latest contact information.

ZOOMRY

ZOOMRY