Time is a very crucial factor in busy ports.The use of each and every space is a checkbox in optimal usage of time.Thus,how to enhance the transport efficiency given the scarcity of space has emerged as a perpetual process.

Harbor freight truck unloaders have over time adopted a special place as some of the most effective equipment that can be used in today’s cargo handling systems in the ports because of their flexibility and high transport rates.They are vital in works increase efficiency,decrease costs and that protect both workers and employers.

A harbor freight truck unloader as the name may suggest is equipment that is specifically used to unload good at the ports.According to the experts,the earliest unloader started to appear as far back as the 19th century.They have advanced with technolog;today t hey are more efficient and intelligent.As it is shown,nowadays there are possibilities for different types of cargo to be unloaded by harbor freight truck unloaders,including bulk and containers with necessary features for different ports.

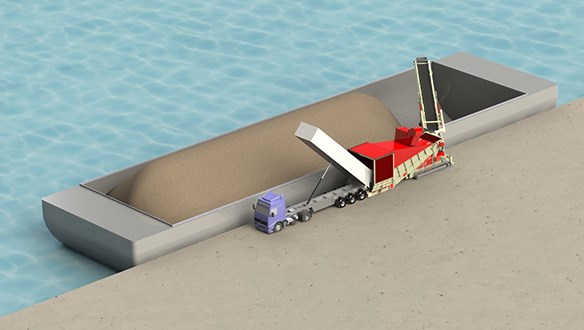

Truck unloaders are moderately big and heavy yet efficient machines at harbor freight.They often include lift ing equipment,

belt conveyors,and other unloading equipment.The working principle is simple:trucks discharge materials into the hopper which are then conveyed by way of conveyors to their Various parts of the plant.Due to the flexibility of the truck unloader,the lots are well arranged in a smooth and even manner.Despite the fact that this process may seem not very complicated it demands correct management at each point,thereby excluding an excessive quantity of manual operations.

II.Major Categories of Truck Unloaders at Harbor Freight

2.1.Fixed Unloaders For Trucks At Harbor Freight

Fixed harbor freight truck unloaders are mounted and permanently positioned at a specific location within the ports,and they are mainly used for operational objectives of dealing with sheer quantities of the goods.It has high stability and strong bearing capacity,used for large-scale port,long-term stable,fixed by cargo flow patterns.The two most usual types are the bridge unloader and the gantry unloader,which are distinguished by strong construction and large carrying capacity,but low adaptability.

2.2.Mobile Harbor Freight Truck Unloaders

On the other hand,mobile harbor freight truck unloaders for the most part are more choric in demeanour and are free to maneuver around the port in as and when they are needed.Due to the use of battery power,they are suitable for small to medium-sized ports or for a situation that calls for frequent position change.That is why the real benefit of mobile unloaders is their ability to operate and adapt to the current work conditions.Some of the popular models are tire unloaders,and track unloaders.

III.Pros of Having Harbor Freight Truck Unloaders

3.1.Increased Work Efficiency

This is one of the biggest benefits that harbor freight truck unloaders have to offer because work productivity is raised to higher levels.The contemporary unloader equipment can discharge significant quantities of cargo within the shortest period,thus cutting down the time ships spend in the ports.For instance,the application of high-efficiency unloader can load or unload the thousands of tons of cargo per hour which means the higher throughput of the port’s cargo.

3.2.Reduced Labor Costs

With the increase of the automation degree of harbor freight truck unloaders,more and more operations that need manual action can be mechanized.This helps to overcome the problem of large dependence on labour and also cuts down on labour expenses.Machines can do a job faster and more efficiently without having to be innacurate.

3.3.Enhanced Safety

Today there are many types of harbor freight truck unloaders and their construction is carried out considering safety.Some of the safety protection devices that are incorporated on the equipment include the emergency stop buttons and the anti-slip systems which enhance safety in the sensitive surroundings.Reduction of manipulating operations also leads to decreased incidence of laborers’accident because of utilization of automated equipment.

IV.How to Tips:Selecting the Right Harbor Freight Truck Unloader

4.1.Selecting the right harbor freight truck unloader

In regard to the harbor freight truck unloader,there are certain concrete requirements to consider,such as the type of cargo,the ports conditions,and the amount of operations.Accordingly,to select the right model and specifications of the equipment take the following into consideration.For instance,if the ports deal with large volumes of bulk cargo they would prefer to use the efficient fixed unloaders while ports that constantly have to change positions would prefer mobile unloaders.

4.2.Maintenance and Upkeep

As for harbor freight

truck unloaders,the feature of sustainable stability requires constant maintenance and proper care.Daily,fortnightly,monthly and other necessary checks should be carried out on all component of the equipment to check on the kind of performance it has and remedy any problem.If appropriately done,this may increase the equipment’s lifespan.Also,the operators of the equipment should undergo professional training to enable them apply appropriate maintenance measures and use the equipment competently.

ZOOMRY

ZOOMRY