Product Description

The large-inclination conveyor overlaps with various crushing, screening, feeder, stacker and reclaimer and other equipment on the production line, and is used for transporting various bulk materials in the factory area;

It can be flexibly arranged according to the needs of the production line, the length is based on site needs, and the inclination angle can be selected arbitrarily within -30°-30°.

Specification

|

Belt Width |

800mm;914mm(36'');1000mm;1200;1400mm;1600mm; (Customized)

|

|

Length |

5km;10km;15km;20km;25km;30km (Customized) |

|

Inclination |

-30°~+30° |

|

Capacity |

0-15000m3/h |

|

Material particle size |

≤300mm |

|

Belt Speed |

0.6~4.5m/s |

|

Pulley Size |

400mm~1800mm(Diameter) |

|

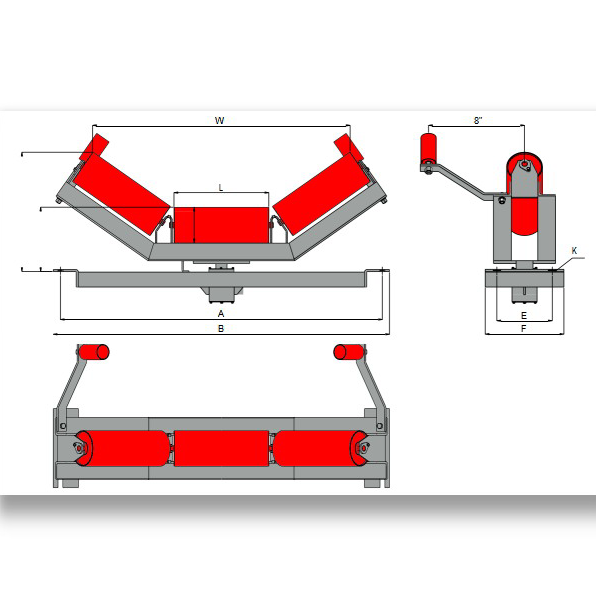

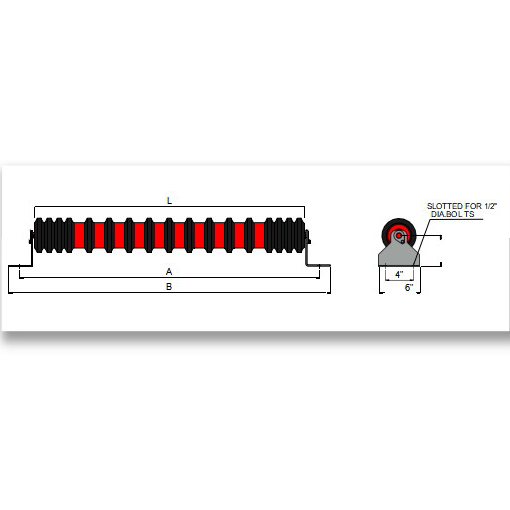

Idler Size |

89mm~219mm(Diameter) |

Details

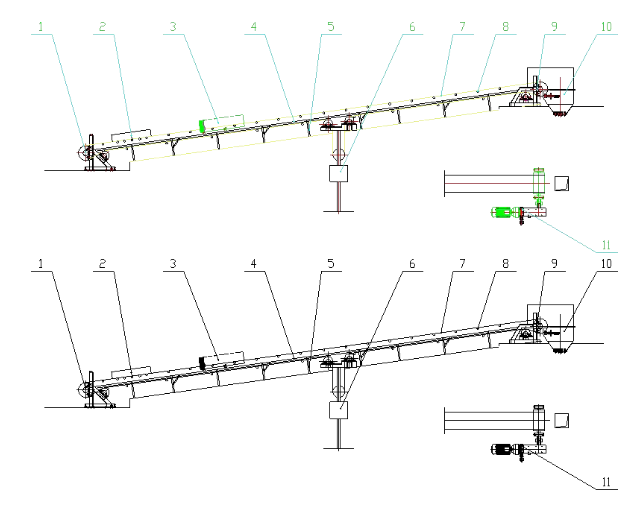

1 Tail pulley and frame 2 Guide chute 3 Rain Cover/Dust cover 4 Middle rack stringer 5 Outrigger

6 Tensioning device 7 Belt 8 Idler 9 Head pulley and frame 10 Hopper 11 Drive system

Belt Sway Switch

Detect whether the belt is deviating and send out a slight alarm or shutdown signal. Deviation will damage the belt and cause safety accidents. Deviation switches need to be purchased and installed in pairs

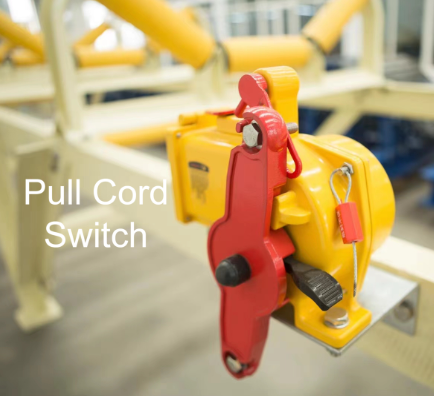

Pull Cord Switch

Pull the wire rope to realize the switch action, which is used for emergency shutdown. It is a safety switch and is arranged along the entire length of the fuselage.

When an emergency occurs on the belt conveyor, the conveyor can be stopped urgently at any position. There are single-sided and double-sided arrangements. They are generally used in conjunction with walkways.

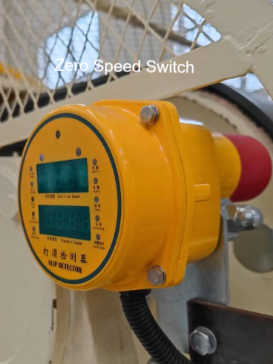

Zero Speed Switch

Detect whether the belt is slipping with the head roller. After slippage occurs, the Conveyor Belt speed will decrease. When the transport volume is overloaded, the belt tension is insufficient, or the rubber layer of the driving roller is worn out, slippage may easily occur. The conveyor belt speed can be monitored (also the rotational speed is calculated) or the drum rotation speed can be monitored.

If the belt conveyor in the stacker encounters an unexpected situation, such as a power outage or a broken wire rope, the stacker has a self-protection function:

1. The winch motor has a self-locking function of 0.01 seconds when the power is cut off

2. The stacker has 2 mechanical mechanisms If stuck, the internal unit will not slip to the bottom all at once. There are two designs in the middle to prevent jamming.

The large-inclination conveyor mainly increases the friction between the material and the conveyor belt by increasing the pressure or contact surface between the material and the conveyor belt, so that the material will not slide down during the process of increasing the inclination angle, occupying a small area but have high operating efficiency.

Applicaion and Cases

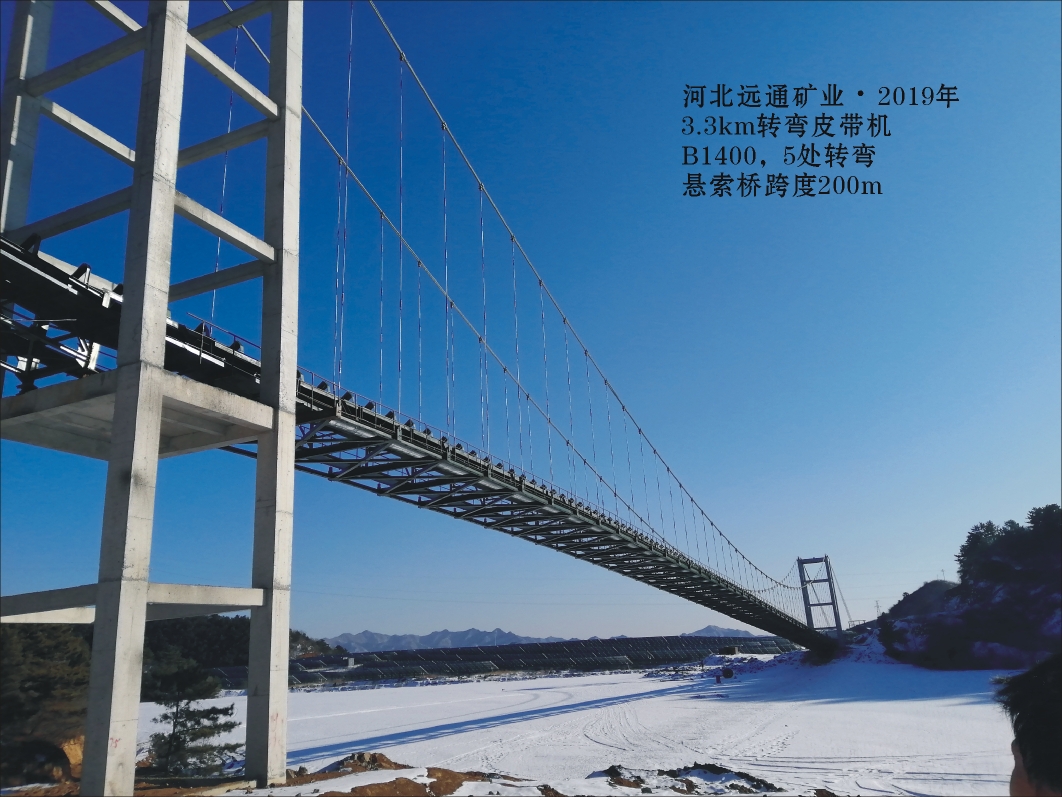

2019

Hebei Yuantong Mining

Length: 3.3km Belt width 1400mm

5 turns

Suspension bridge span 200m

Year 2014

Inner Mongolia Abaga Gold Mine Mining

Length: 5100m Bandwidth 1000mm

Turning angle: 61°

2019

Southeast Mining

Length: 8.6km Belt width 1200mm

8 turns

Suspension bridge span 200m

Year 2014

Huaxia Jianlong Group

Length: 3km, belt width 1200mm

Turning angle: 50°

Advantage

1.It can convey bulk materials at a large angle, greatly shortening the machine length, reducing the space, and completely solving the conveying angle that ordinary belt conveyors cannot reach.

2. Mechanized conveying of materials can reduce project investment costs by approximately 20% to 40%.

3. High degree of standardization, simple structure, easy maintenance, safe and reliable operation.

4. Can transport various bulk materials.

5. The process layout is simplified, flexible, convenient and has many forms. It can replace the combined unit of horizontal conveyor and bucket machine, two machines in one or three machines in one.

6. The belt has high strength and long service life.

Our after-sales service:

1)Installation guide;

2)Provide drawings and instructions;

3)On-site guidance of dispatched engineers;

4)The machine has a long warranty of 2 years ;Roller warranty 50,000 hours.

Video

For belt conveyor and mobile telescopic stackers, if to make the machine running for long time, client need to do the vulcanizing at site.

We can supply the vulcanizing machine with the telestacker or long distance belt conveyor system.

The site vulcanizing work can be done with the following steps:

How to do the site Conveyor belt vulcanizing

ZOOMRY

ZOOMRY